Artificial intelligence-based Modeling Mechanisms for Material Analysis and Discovery

Keywords:

Material analysis,Modeling mechanisms, AI simulations,Material analysisAbstract

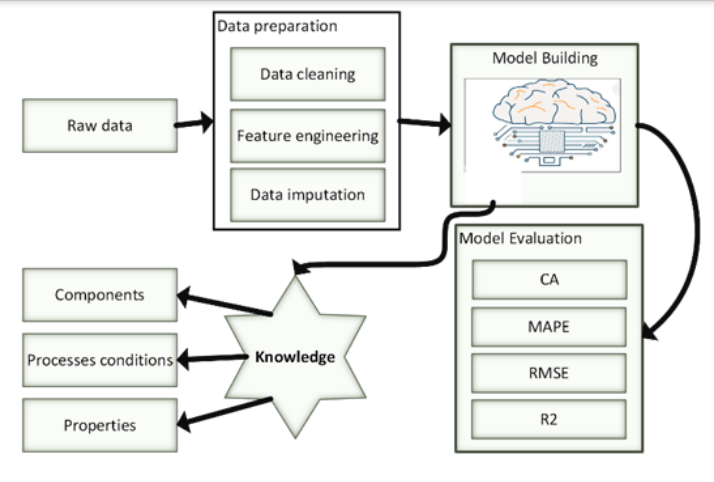

Artificial intelligence-based materials application is one of the hot topics in the field of materials science. Materials are widely used in the space industry, cutting tools, thermal and electrical insulators, and refractory materials. The conventional experiments and statistical approaches usually require more resources and time. Thus, the need for Artificial intelligence applications in the simulation and exploration of novel materials is increasing. Recently, AI has been applied to materials for improving efficiency and prediction accuracy; however, there are many limitations due to the lack of benchmark datasets, advanced pre-processing mechanisms, prediction modelling mechanisms, and simulation tools in the materials literature. Thus it is challenging to identify optimal learning models, including algorithm selection, the architecture of models, data processing, and simulation mechanisms. In this paper, we attempt to review experimental and computational data-based AI mechanisms. Furthermore, the current research status is analyzed for using artificial intelligence techniques in material simulation tools and discovering new materials. Finally, we present research issues of AI-based application realization in materials science.

References

Iqbal, N., & Kim, D. H. (2022). Iot task management mechanism based on predictive optimization for efficient

energy consumption in smart residential buildings. Energy and Buildings, 257, 111762.

Jamil, F., & Kim, D. (2021). An ensemble of prediction and learning mechanism for improving accuracy of

anomaly detection in network intrusion environments. Sustainability, 13(18), 10057.

Imran, Imran, et al. "Using Machine Learning Algorithms for Housing Price Prediction: The Case of Islamabad

Housing Data." Soft Computing and Machine Intelligence 1.1 (2021): 11-23.

Imran, M., Zaman, U., Imtiaz, J., Fayaz, M., & Gwak, J. (2021). Comprehensive survey of iot, machine learning,

and blockchain for health care applications: A topical assessment for pandemic preparedness, challenges, and

solutions. Electronics, 10(20), 2501.

Zaman, U., Mehmood, F., Iqbal, N., Kim, J., & Ibrahim, M. (2022). Towards Secure and Intelligent Internet of

Health Things: A Survey of Enabling Technologies and Applications. Electronics, 11(12), 1893.

Qayyum, F., Kim, D. H., Bong, S. J., Chi, S. Y., & Choi, Y. H. (2022). A Survey of Datasets, Pre-processing,

Modeling Mechanisms, and Simulation Tools Based on AI for Material Analysis and Discovery. Materials,

(4), 1428.

Olson, G.B., 2000. Designing a new material world. Science, 288(5468), pp.993-998.

Sitek, W., Trzaska, J. and Dobrzański, L.A., 2006. An artificial intelligence approach in designing new materials.

Journal of Achievements in Materials and Manufacturing Engineering, 17(1-2).

Ramprasad, R., Batra, R., Pilania, G., Mannodi-Kanakkithodi, A. and Kim, C., 2017. Machine learning in

materials informatics: recent applications and prospects. npj Computational Materials, 3(1), pp.1-13.

Iqbal, N., Khan, A. N., Rizwan, A., Qayyum, F., Malik, S., Ahmad, R., & Kim, D. H. (2022). Enhanced timeconstraint aware tasks scheduling mechanism based on predictive optimization for efficient load balancing in

smart manufacturing. Journal of Manufacturing Systems, 64, 19-39.

Virshup AM, Contreras-García J, Wipf P, Yang W, Beratan DN. Stochastic voyages into uncharted chemical

space produce a representative library of all possible drug-like compounds. J Am Chem Soc 2013;135(19):7296–

link1

T. Zhou, Z. Song, and K. Sundmacher, 'Big Data Creates New Opportunities for Materials Research: A Review

on Methods and Applications of ML for Materials Design', Engineering, vol. 5, no. 6, pp. 1017–1026, Dec. 2019,

doi: 10.1016/j.eng.2019.02.011.

Jain A, Ong SP, Hautier G, Chen W, Richards WD, Dacek S, et al. Commentary: the materials project: a

materials genome approach to accelerating materials innovation. APL Mater 2013;1(1):011002. link1

Michalski RS, Carbonell JG, Mitchell TM, editors. ML: an AI approach. Berlin: Springer-Verlag; 2013. link1

Agrawal A, Deshpande PD, Cecen A, Basavarsu GP, Choudhary AN, Kalidindi SR. Exploration of data

science techniques to predict fatigue strength of steel from composition and processing parameters. Integr

Mater Manuf Innovation 2014;3:8.

Karak SK, Chatterjee S, Bandopadhyay S. Mathematical modeling of the physical and mechanical properties

of nano-Y2O3 dispersed ferritic alloys using evolutionary algorithm-based neural network. Powder Technol

;274:217–26. link1

Pilania G, Mannodi-Kanakkithodi A, Uberuaga BP, Ramprasad R, Gubernatis JE, Lookman T. ML bandgaps

of double perovskites. Sci Rep 2016;6:19375. link1

Jinnouchi R, Asahi R. Predicting catalytic activity of nanoparticles by a DFTaided machine-learning algorithm.

J Phys Chem Lett 2017;8(17):4279–83. link1

Zhou T, Jhamb S, Liang X, Sundmacher K, Gani R. Prediction of acid dissociation constants of organic

compounds using group contribution methods. Chem Eng Sci 2018;183:95–105. link1

Aghaji MZ, Fernandez M, Boyd PG, Daff TD, Woo TK. Quantitative structure– property relationship models

for recognizing metal organic frameworks (MOFs) with high CO2 working capacity and CO2/CH4 selectivity

for methane purification. Eur J Inorg Chem 2016;2016(27):4505–11. link1

Sharma V, Wang C, Lorenzini RG, Ma R, Zhu Q, Sinkovits DW, et al. Rational design of all organic polymer

dielectrics. Nat Commun 2014;5:4845. link1

Jha, D., Ward, L., Paul, A., Liao, W.K., Choudhary, A., Wolverton, C. and Agrawal, A., 2018. Elemnet: Deep

learning the chemistry of materials from only elemental composition. Scientific reports, 8(1), pp.1-13.

Ward, L., Dunn, A., Faghaninia, A., Zimmermann, N. E., Bajaj, S., Wang, Q., ... & Jain, A. (2018). Matminer: An

open-source toolkit for materials data mining. Computational Materials Science, 152, 60-69.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2022 Journal of Intelligent Pervasive and Soft Computing

This work is licensed under a Creative Commons Attribution 4.0 International License.

Articles are licensed under an open access Creative Commons CC BY 4.0 license, meaning that anyone may download and read the paper for free.